Product number:

9731015

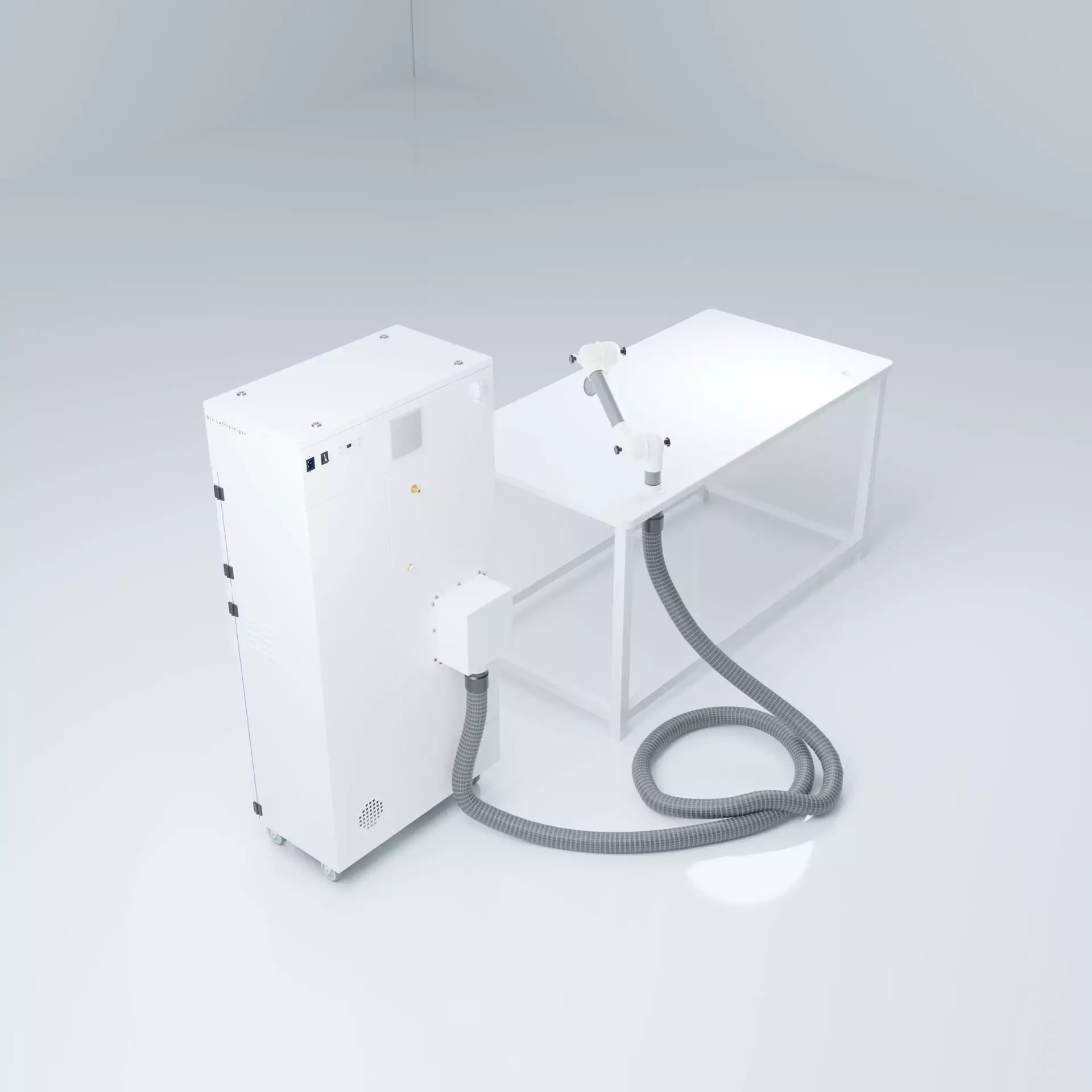

Extraction unit type LFE 101 for laser application

(115-230V; 50-60Hz)

€7,795.00*

Delivery time on request

Extraction unit type LFE 101 for laser application

(115-230V; 50-60Hz)

EAN: 4251906211243

The mobile LFE 101 filter unit has been specially designed for use in environments in which it is necessary to extract fumes and particulate matter that are generated due to cleaning or laser cutting.The process air is first taken into the LSE’s rear-mounted suction housing and is channelled to the filter compartment via a baffle plate. In the first filter stage, the inlet air passes through three filter cartridges which separate out the fumes and dusts using the surface filtration principle. The filter cartridges are cleaned fully automatically by compressed air depending on their level of contamination. Please note that a compressed air connection is required.

The removed dust particles arrive in a dust collecting tank below the filter cartridges. The dust collecting tank can be easily removed via a service door for emptying.

In the second filter stage, the air stream is guided through a cassette that is filled with an activated carbon granulate. This filter stage possesses a very large filter surface for the absorption of gases and odours.

The unit’s final filter stage consists of a HEPA disposable filter that removes any remaining fine particles. An automatic filter monitoring system indicates when it is necessary to change the filter cartridges or the HEPA final stage.

The suction device is equipped with powerful high-pressure turbines that can be continuously adjusted to increase or reduce the suction power. All the operating states can be output or set by the display.

In addition, the LFE unit is also equipped with a particle sensor in the pneumatic area in order to detect any potential filter breakthroughs and shut down the unit automatically in the event of an emergency.

The LFE is equipped with a Harting interface as standard, making it possible to control the unit externally, e.g. via laser.

Standard equipment:

- 3 x nanofilter cartridges, each with a filter surface area of 2.7 m²

- Activated carbon cassette filled with 7 kg of granulate

- H13 HEPA final stage

- Particle sensor

- Harting industrial interface for external control

Properties

| Blower type: | Dauerläuferturbine |

|---|---|

| Control interface: | Harting-Schnittstelle |

| Intake manifold (mm): | wahlweiser Anschluss |

| Interface description: | Pin 1&2: Start-Stopp, Pin 3: ext. Spannungseingang, Pin 4: ext. Meldung Störung, Pin 5: ext. Meldung |

| Volumetric flow (m³/h): | 400 |

| max. pressure (Pa): | 15.000 |

| Engine power (kW): | 0,6 |

| Supply voltage (V): | 115 / 230 |

| Connection frequency (Hz): | 50 / 60 |

| Current consumption (A): | 6,8 |

| Automatic cleaning: | yes |

| Filter control: | Siemens S7 |

| Pre-filter: | baffle plate |

| main filter: | 3x Filterpatronen ECN 2,7 m² ; 1x HEPA H13 |

| final filter: | Aktivkohle, Typ FK (Füllung ca. 7 kg) |

| Ausblas: | über Ausblasgitter auf der Anlagenrückseite |

| Sound level (dB(A)): | 68 |

| Weight (kg): | 168 |

| Width (mm): | 751 |

| Depth (mm): | 400 |

| Height (mm): | 1.590 |

| Colour: | RAL 9010 (Reinweiß) |