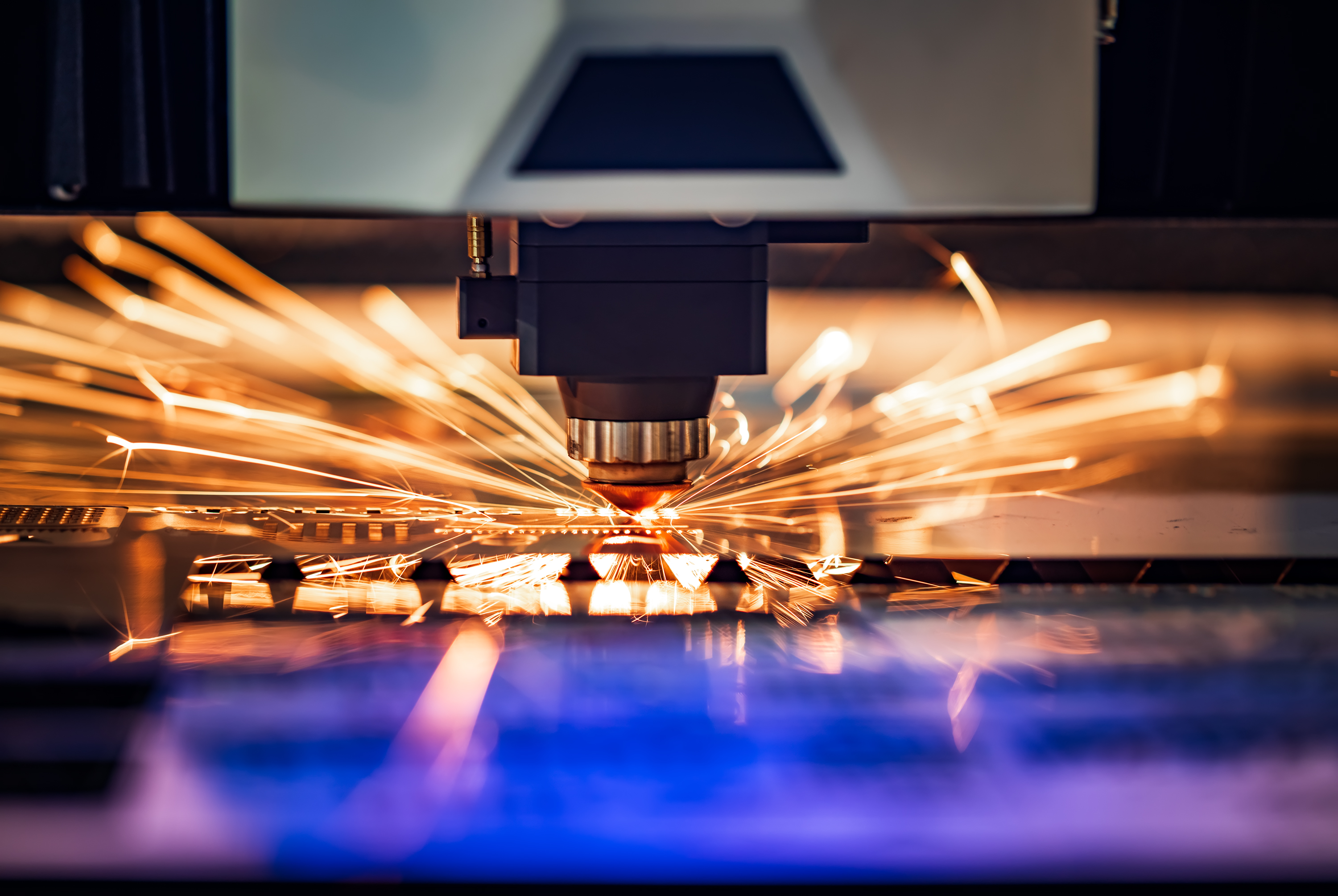

Precise laser fume extraction for laboratories & research

Optimum working conditions for precise results

In laboratories and research facilities, precise laser fume extraction is crucial to ensure a safe and healthy working environment. Protect your valuable employees and sensitive equipment from harmful emissions and particles generated during laser processing.

Our specially developed extraction systems offer maximum efficiency in removing even the finest particles and gases. At the same time, they ensure low-noise operation to create a pleasant working atmosphere. Thanks to their compact design, they are ideal for confined laboratory spaces and can be flexibly adapted to your work processes.

Laser filters: The centrepiece of your extraction system

The efficiency and safety of a laser fume extraction system depends largely on the quality of its filters. TEKA relies on high-performance laser filters, specially designed for the challenges of Laser processing have been developed.

Our filters offer:

- Maximum separation efficiency: Even the finest particles and harmful gases are reliably retained.

- Long service life: Robust materials and innovative filter technologies ensure a long service life and reduce maintenance costs.

- Easy filter change: Quick and uncomplicated maintenance for minimal downtime.

- Comprehensive protection: HEPA filters and activated carbon filters provide protection against a wide range of pollutants.

The right filter for every application:

We offer a wide selection of laser filters for different laser types and processing methods. Whether laser cutting, -engraving or welding - we will find the optimum filter solution for your requirements.

The underestimated danger: laser smoke and laser dust

Laser cutting and laser welding not only produce precise results, but also highly toxic gases: Laser smoke and laser dust. These fine particles, which are produced during cutting, engraving or welding, can have serious consequences for your health and your machines.

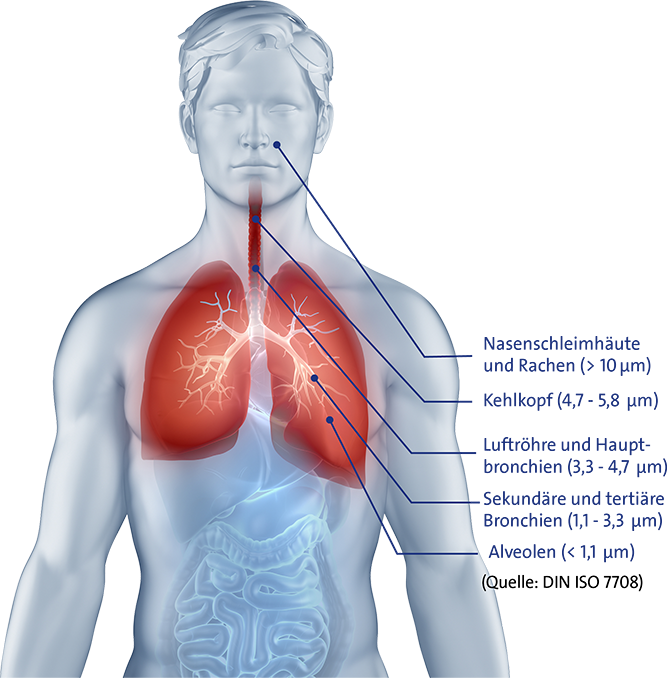

Health risks:

- Respiratory diseases: Inhalation of laser fumes can cause respiratory irritation, coughing, bronchitis and even asthma.

- Eye irritation: The fine particles can irritate the eyes and cause inflammation.

- Skin problems: Contact with laser smoke can cause allergic reactions and skin irritation.

- Long-term effects: In some cases, the substances contained in laser smoke can even be carcinogenic.

Laser extraction: Stationary or mobile - the right solution for your requirements

The choice of the right extraction system depends largely on your individual requirements and spatial conditions. At TEKA, we offer you both stationary and mobile solutions, to meet every requirement.

Stationary extraction:

- Ideal for fixed workstations and large laser systems

- High extraction performance and filter capacity for intensive applications

- Space-saving integration into your working environment

- Reliable continuous operation for maximum productivity

Mobile extraction:

- Flexible use at different workstations

- Compact and lightweight for easy handling

- Ideal for changing locations and smaller laser devices

- Cost-efficient solution for occasional applications

Whether you need a stationary or mobile solution, we will be happy to advise you on the best laser fume filtration for your specific requirements. Contact us today and let our experts support you!

FAQ - Frequently asked questions about laser smoke extraction

What is laser fume extraction and why is it important?

There are different types of extraction systems, including:

- Mobile extraction units: Can be used flexibly for changing workplaces.

- Stationary extraction systems: Powerful for large production halls.

- Point extraction systems: Capture smoke directly at the point of origin.

- Room ventilation systems: Ensure an overall improvement in air quality.

What are the health risks of laser smoke and laser dust?

Laser smoke and dust can cause a variety of health problems, including:

- Respiratory diseases: Cough, Bronchitis, Asthma

- Eye irritation and damage

- Skin irritation and allergic reactions

- In some cases even cancer

How do laser smoke and dust affect my machines and research results?

- Wear and tear: Dust particles can be deposited in moving parts and lead to increased wear.

- Malfunctions: Dust can affect sensors and optics and lead to malfunctions.

- Contamination: In laboratories and research facilities, dust can falsify samples and results.

- Production downtime: Machine damage caused by dust and smoke can lead to costly downtime.

What legal regulations apply to the handling of laser smoke?

What types of laser smoke extraction systems are there?

There are different types of laser smoke extraction systems, including:

- Stationary systems: These are permanently installed and are suitable for larger work areas or if several machines are to be connected to one system.

- Mobile systems: These are flexible in use and can easily be used at different workstations.

- Desktop units: These are compact and are suitable for smaller laser devices or for occasional use.

How do I choose the right laser smoke extraction system?

Choosing the right extraction system depends on various factors, including

- Type of laser processing (cutting, Engraving, Welding)

- Type and quantity of material being processed

- Size of the work area

- Frequency of use

- Space conditions