Werba Plast relies on the TEKA-FilterCube in a trio

November 10, 2022

Smoke- and dust-free laser use for innovative sales promotion

“The filter lifetimes have increased enormously. For us, this means greatly reduced effort and, most importantly, costs,” says Olaf Lehmann, Head of Production at Werba Plast.

Werba Plast GmbH is a dynamic medium-sized company, headquartered in Rosstal near Nürnberg. Since it was founded in 2003, this family-run business has become one of the leading manufacturers of industrial goods for the retail trade. The manufacturer is well-known for its presentation displays, sales displays, product separators, fixtures and accessories for electronic price displays, product lifters and pushers, scanner rails and stands. The focus is always on ensuring the optimum presentation and price display for fruit and vegetables, meat, books as well as pharmaceutical and drugstore products. The company’s customers include the foodstuffs industry, bookstores, chemists or drugstores as well as other retailers.

Its aim is to retain its position as a well-respected company for the attractive and functional presentation and identification of products. That is why it uses state-of-the-art technologies in its production processes. Werba Plast has long been using laser cutting and engraving technology during the processing of its materials. Wood and a variety of plastics in material thicknesses of between 1.8 mm and 15 mm are machined simultaneously at three workstations. Using different laser powers, namely 230W, 690W and 850W, the manufacturing materials can be cut or engraved exceptionally cleanly and precisely. This generates very large amounts of dust and fumes at the three 3050 x 2050 mm laser cutting tables. As a result, it was necessary to change the filters at the extraction and filter system that was previously in use every week.

“When we decided to modernise our extraction and filter system, our most important aim was to have a system which offered the outstanding extraction performance necessary to cope with the volumes of dust and fumes coupled with very long filter lifetimes, because the previous solution was extremely labour-intensive and expensive,” explains Olaf Lehmann, Head of Production at Werba Plast.

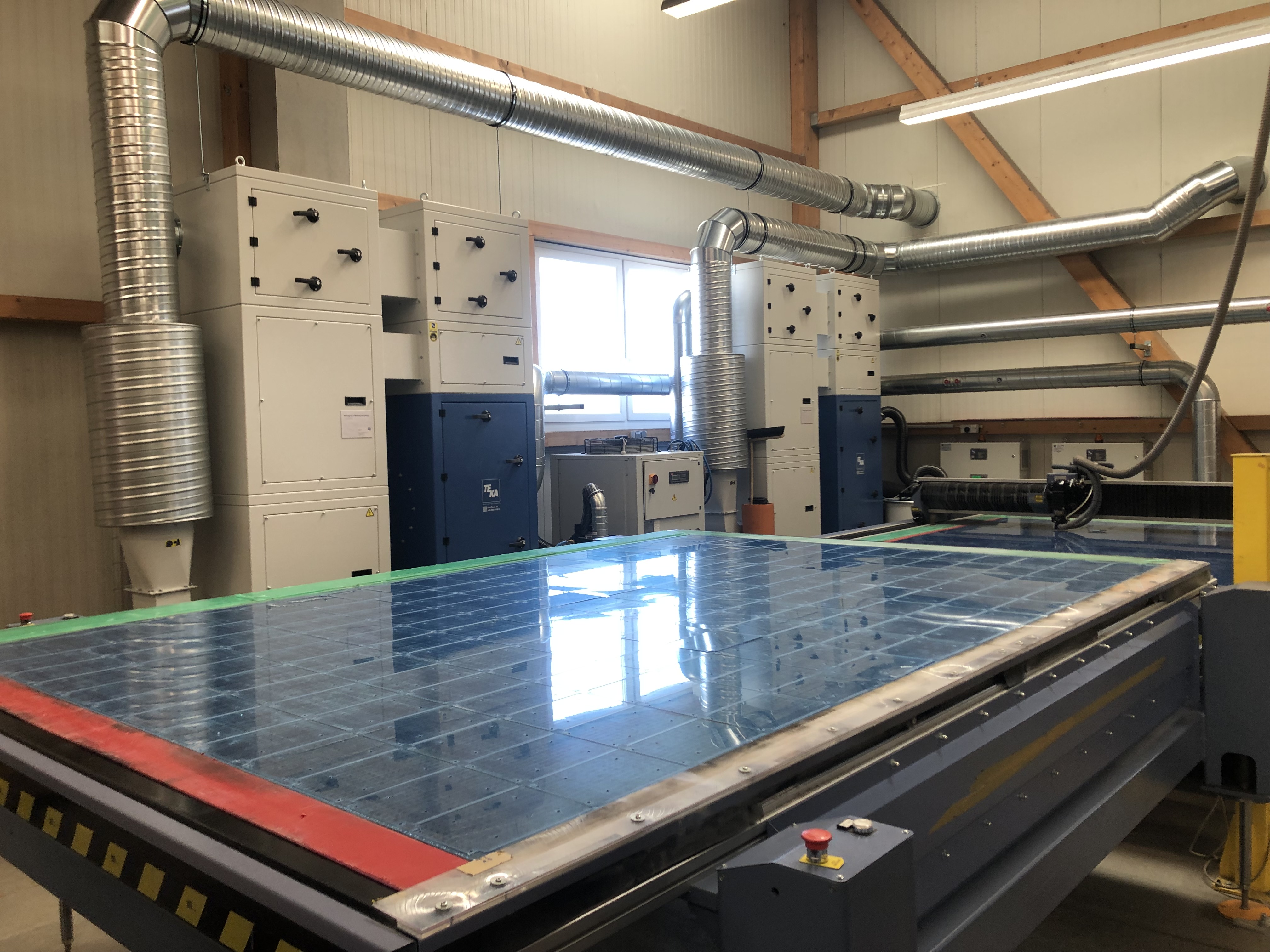

To provide an intelligent and also particularly healthy solution, all three lasers were connected to a TEKA FilterCube in order to reduce the dust and fume emissions directly at the place of production. A dual-module system equipped with filter and activated carbon cartridges was chosen for this application.

Space-saving all-rounder

The TEKA FilterCube is an extraction unit with a modular design that can be used for practically any fume and dust filtration application. As a stationary unit, it takes in the fumes and dusts that are generated at Werba Plast through a pipe, cleans the contaminated air with an efficiency of almost 100 percent and then guides it from the working area to the exterior.

The contaminated particulate matter remains on the surface of the filter cartridges and falls into a dedicated container during the automatic filter cleaning operations. The Easy Clean Plus cartridges that are used in the FilterCube are made from a grooved polyester material with a nanofibre lining and were specially developed for removing particulate matter from the welding fumes and dusts that are generated by flame, plasma or laser cutting processes. In particular, particles that are capable of entering the alveoli

(< 0.4 µm) are filtered out exceptionally efficiently. The use of Easy Clean Plus cartridges greatly improves separation efficiency, meaning that a filtration level of nearly 100 % is very quickly achieved. As a result, under identical operating parameters, they offer considerably improved filtration performance with significantly lower pressure losses than conventional filter media made from polypropylene or PTFE. The unit is also equipped with activated carbon cartridges that absorb almost all the generated gases and consequently bind in any odours.

Preventing the filters from sticking

The cutting of Plexiglas, plastic and similar materials produces a sticky smoke that can soon clog up the filters. To prevent this, each of the extraction units at Werba Plast is equipped with a dispensing mechanism. After each cleaning operation, a filter aid is applied to the filters and acts almost like a protective coating on the surface of the cartridges. The process dust binds with this and is deposited only superficially on the filter cartridge. This additional mechanism greatly extends the lifetime of the filter cartridges.

“The FilterCube is an all-rounder. The fact that it could be compactly installed right next to the laser tables in a space-saving way despite the limited space available made it the ideal solution for Werba Plast,” explains Michael Kneuer, the responsible member of the TEKA field service team who advised the company and ensured that the project was brought swiftly to fruition. Once the order had been awarded at the end of 2021, it was possible to install the FilterCube as early as February 2022. A satisfied Olaf Lehmann sums things up: “Since the units were started up in February 2022, we have not yet had to change any filters”.

Image caption (piping system): The piping system was adapted to the layout of the room.