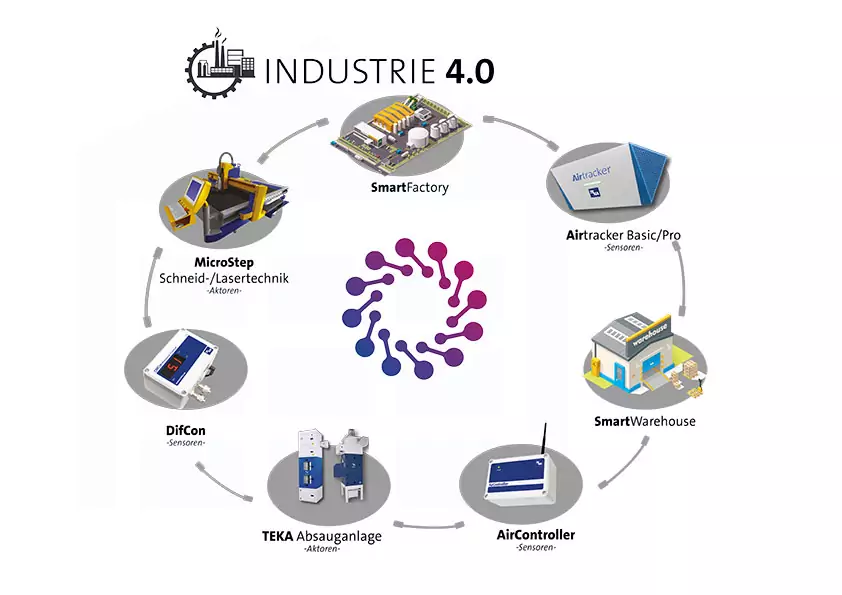

Industry 4.0

Industry 4.0

refers to the integration of industrial production with state-of-the-art information and communication technology.

This development is the increasing digitalisation of the economy and society, smartphones, tablets, the internet and smart homes. It is permanently changing the way we will produce and work in Germany in the future.

Smart Factories is the name of the game, says Erwin Telöken, Managing Director of TEKA GmbH. The technical basis for this are intelligent, digitally networked systems that enable largely self-organised production. People, machines, systems and products communicate with each other.

Production and logistics processes between companies in the same process are intelligently networked with each other to make production even more efficient, flexible and healthy.

If all information is available in real time, a company can, for example, react early to the availability of certain spare parts, missing parts, as well as incorrect behaviour, etc.

By using the TEKA sensors - AirTracker-DifCon series and the actuators of the EcoCube and FilterCube series, production processes can be controlled across companies when networking cutting laser systems from MicroStep, for example, in such a way that resources and energy are saved, says Telöken.

Intelligent sensors/actuators help to manage the errors that occur in all companies and cannot be completely avoided. Overall, intelligent networking can increase the economic efficiency of production, strengthen competitiveness and increase production flexibility.

TEKA - Industry 4.0 - The future is TODAY

This development is the increasing digitalisation of the economy and society, smartphones, tablets, the internet and smart homes. It is permanently changing the way we will produce and work in Germany in the future.

Smart Factories is the name of the game, says Erwin Telöken, Managing Director of TEKA GmbH. The technical basis for this are intelligent, digitally networked systems that enable largely self-organised production. People, machines, systems and products communicate with each other.

Production and logistics processes between companies in the same process are intelligently networked with each other to make production even more efficient, flexible and healthy.

If all information is available in real time, a company can, for example, react early to the availability of certain spare parts, missing parts, as well as incorrect behaviour, etc.

By using the TEKA sensors - AirTracker-DifCon series and the actuators of the EcoCube and FilterCube series, production processes can be controlled across companies when networking cutting laser systems from MicroStep, for example, in such a way that resources and energy are saved, says Telöken.

Intelligent sensors/actuators help to manage the errors that occur in all companies and cannot be completely avoided. Overall, intelligent networking can increase the economic efficiency of production, strengthen competitiveness and increase production flexibility.

TEKA - Industry 4.0 - The future is TODAY