As an expert in industrial extraction technologies, TEKA goes one step further:

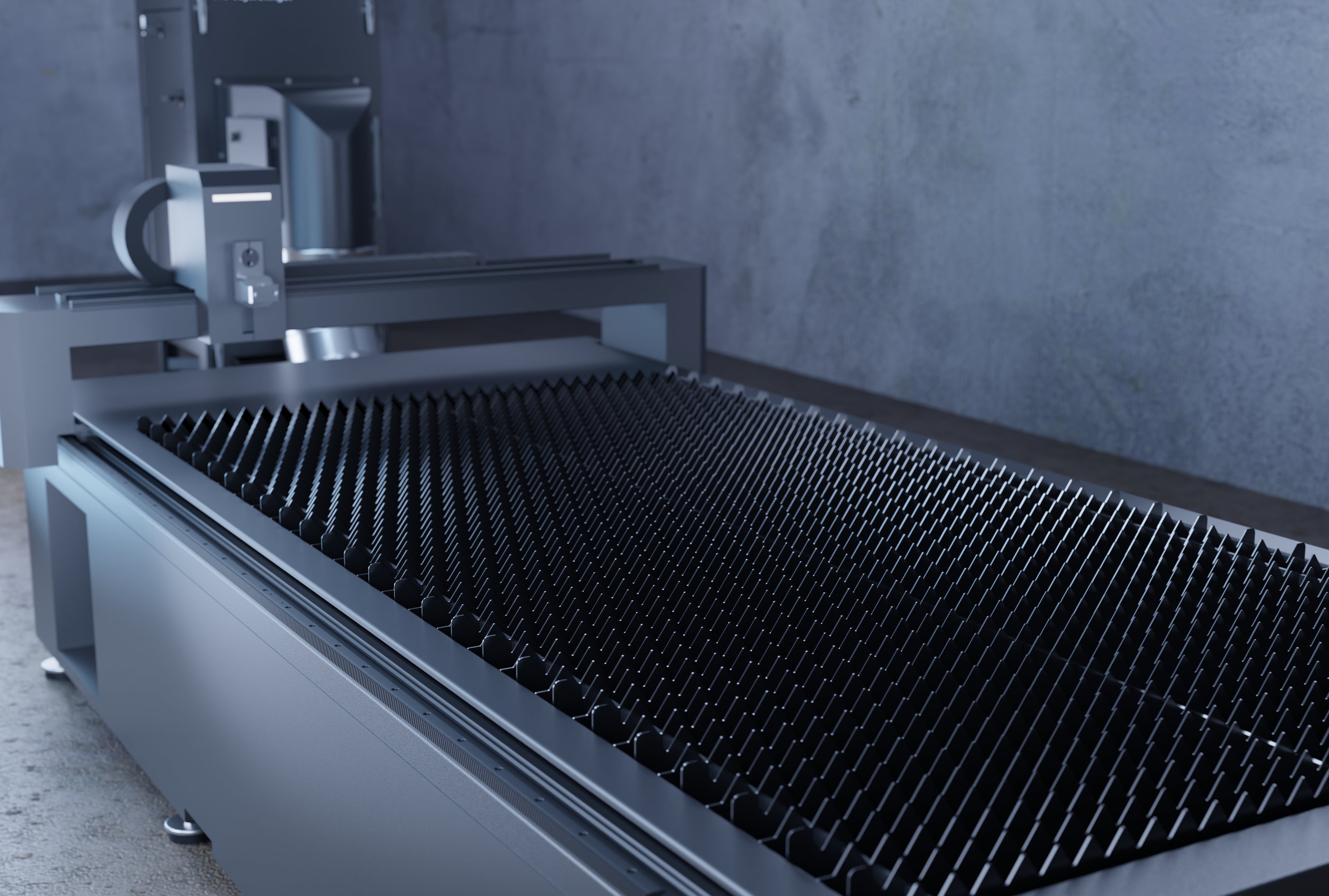

The AirCut plasma cutting system combines state-of-the-art cutting technology with integrated extraction to optimise both quality and safety in metalworking. This complete solution was developed from the desire to offer customers not only precise technology, but also a clean and healthy working environment. TEKA thus demonstrates how innovative technologies and years of experience can be perfectly combined.

Advantages of the TEKA AirCut plasma cutting system

-

Precise cutting and clean air: It combines state-of-the-art cutting technology with an effective extraction system that immediately removes pollutants and creates a healthy working environment.

- Legal compliance: It fulfils all relevant emission and health and safety regulations.

- Simple operation: With user-friendly software, you can flexibly customise the AirCut to your requirements.

-

Industry 4.0-capable: It offers a future-proof solution thanks to modern networking technologies.

-

Quick installation and maintenance: The AirCut is easy to install and requires little maintenance.

The complete solution for precise plasma cutting

- Robust flame-cutting table made of welded structural steel for maximum stability

- Helical gearing in all X-Y transfer systems for high accuracy

- Automatic extraction table with section control for a clean working environment

- Integrated interface for remote start and power supply to the filter system

- Free-standing operating terminal with industrial PC, 19" screen and I5 processor

- CAD CAM software for operation incl. component library

- Status LED display on the guide machine for operating overview

- Collision protection system for the torch head

- Automatic cutting height adjustment for even cuts

- Analogue interface for Hypertherm and Kjellberg power sources

- Panasonic I4C InfoHub with cloud access

- Industry 4.0 connection via OPC-UA and MQTT services

Precision and flexibility in different versions

The TEKA AirCut series impresses with different versions that can be adapted to your individual requirements - both in terms of application and budget. Whether you want to process medium or large sheet formats, our plasma cutting system offers you a flexible solution that impresses with powerful cutting technology and efficient extraction. Find the right variant that optimises your work processes while remaining economical.

TEKA AirCut "small format" series

The AirCut small format series comprises a cutting table that is suitable forsheet formats up to 1250 mm x 2000 mm and provides a solid basis for precise cutting work.

The integrated filter system removes contaminants directly on site, ensuring a clean and safe working environment, while the power source, including pipework, provides a reliable power supply.

This solution is ideal for companies that want to combine the highest cutting quality with flexible and efficient technology.

TEKA AirCut medium format series

The AirCut medium format series forlarge cutting projects. With a cutting table for sheet formats up to 1500 mm x 3000 mm it offers an excellent solution for applications that require high precision and flexibility.

The integrated filter system ensures effective pollutant extraction, while the power source including pipework provides a stable and reliable power supply.

This version is the ideal choice for companies that want to carry out larger projects with the highest cutting quality and efficiency.

- High quality at an attractive price: The AirCut impresses with its first-class workmanship and excellent price-performance ratio.

- Including CAD/CAM software: You get everything you need for a seamless start at no extra cost.

- Ideal solution for small and medium-sized companies: Powerful, flexible and customised to your requirements.

- Quickly ready for use thanks to Plug & Play: Installed and ready for production within a day.

TEKA - Your partner for the next generation of plasma cutting

Plasma cutting: Precision and efficiency for your industry

Plasma cutting systems have become an integral part of modern metal processing. They enable fast, precise and flexible processing of all types of metal and offer a cost-effective solution for industrial applications. In particular, the high cutting speeds and versatility make this technology a favoured choice for numerous industries. The TEKA Aircut plasma cutting system offers a promising solution for companies that rely on precise and efficient cutting.

What is plasma cutting?

Plasma cutting is a process in which electrically conductive materials are cut with a high-precision plasma jet. This is generated by the ionisation of gases such as argon, nitrogen or oxygen and reaches temperatures of up to 30,000 °C. This allows materials such as steel, stainless steel, aluminium and copper to be cut with high speed and precision. The flexibility of the process, which is suitable for both thin and thick metals, is particularly noteworthy.

How plasma cutting systems work

The process can be divided into two phases:

- Generation of the plasma jet: Gas is channelled through a nozzle located between the electrode and the workpiece. An electric arc ionises the gas and generates the plasma.

- Cutting the workpiece: The plasma jet reaches extreme temperatures that instantly melt the metal and blow it out of the kerf due to the pressure of the gas.

These properties make plasma cutting particularly suitable for demanding cutting tasks in industry, as it works both at high speeds and with very tight tolerances.

Manual vs. CNC plasma cutting systems

There are two main types of plasma cutting systems: manual and CNC-controlled systems.

- Manual systems: offer a high degree of flexibility and are ideal for smaller workshops and repair work where precision and mobility are required. They are easy to operate and can be quickly adapted to different cutting tasks.

- CNC-controlled systems: Are computer-based machines that automatically perform precise and repeatable cuts. They are ideal for series production and complex cutting patterns, as they are able to quickly implement customised designs thanks to programmed CAD and CAM software.

Areas of application for plasma cutting

Plasma cutting is used in a variety of industrial sectors to cut materials precisely. The main areas of application are:

Metalworking:

- Plasma cutting is often used to cut metals such as steel, stainless steel, aluminium, copper and brass. It is particularly suitable for thicker material thicknesses and can process materials in different shapes and sizes.

Shipbuilding:

- In shipbuilding, plasma cutting is used to cut large steel plates and sheets to produce hull parts and other components.

Automotive industry:

- In automotive production, plasma cutting is used to cut parts from sheet metal, particularly for car bodies and other components.

Construction industry:

- Plasma cutters are important in the construction industry, especially in the processing of steel beams and other heavy metal structures.

Aerospace industry:

- In the aerospace industry, plasma cutting is used for precise cuts in special alloys and metal parts.

Boiler and pipework construction:

- Plasma cutting is used for cutting steel pipes and other metal components in the pipework and boiler industry.

Recycling and demolition work:

- Plasma cutting is also used in recycling to cut scrap metal into smaller parts that can be reused or recycled.

Toolmaking and mechanical engineering:

- Plasma cutters are important in the manufacture of machines and tools as they offer high precision and can cut complex shapes.

The flexibility, speed and efficiency of plasma cutting make it a favoured method for many industrial applications

Advantages of plasma cutting

Plasma cutting systems offer numerous advantages:

- High precision: The plasma jet enables exact cuts with minimal material loss.

- Flexibility: You can cut a wide variety of materials and thicknesses efficiently.

- Cost efficiency: Plasma cutting saves time and resources thanks to fast processing and low production costs.

- Wide range of applications: Ideal for both small workshops and large production operations.

The future of plasma cutting

Plasma cutting technology is constantly evolving. Modern CNC plasma cutters are equipped with advanced sensors and automation technologies that offer even greater precision and efficiency. In addition, new materials and applications are constantly being researched, further expanding the potential of this technology.

No matter what metalworking industry you are in - TheTEKA Aircut plasma cutting system sets the standard in terms of efficiency and innovation, offering the flexibility, speed and precision you need to optimise your production processes. Rely on a reliable and efficient solution to take your production to the next level.